F Edible Oils

Refining of Edible Oils

Edible oils obtained from coconut, corn, cottonseed, olive, palm, peanut, soya bean and sunflower etc. contain gums and other impurities which are removed by degumming, neutralising and bleaching processes.

The Process

The basic principle of these processes can be summarsed as follows:

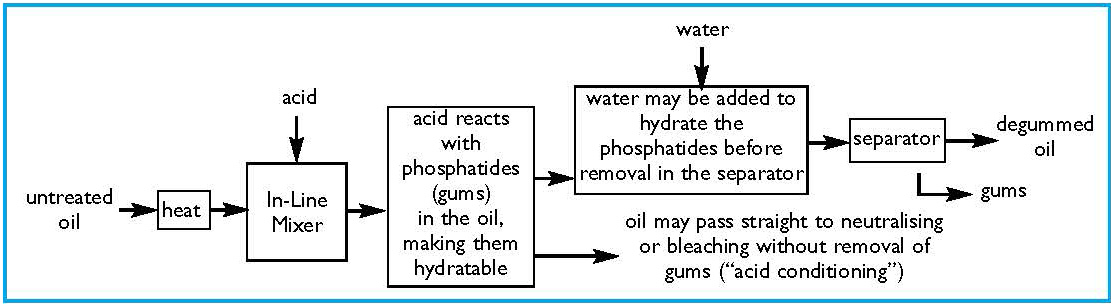

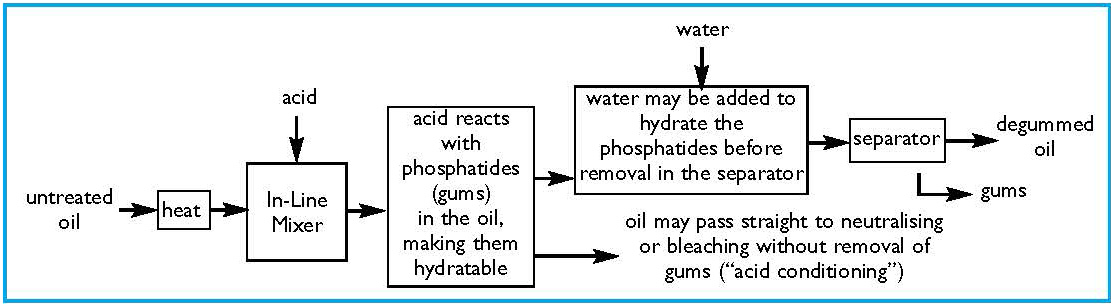

Degumming

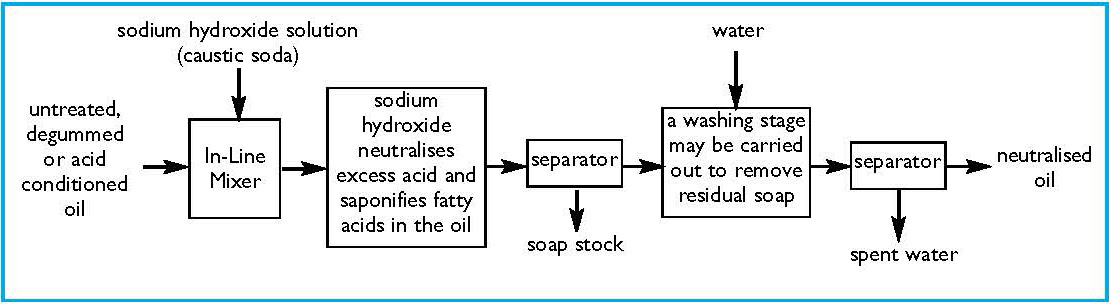

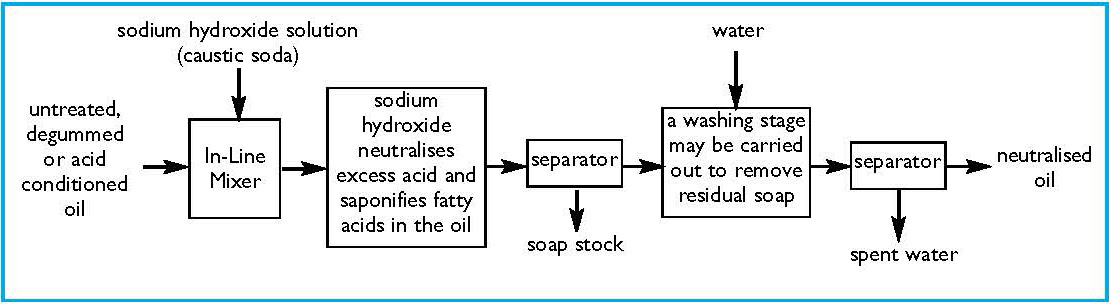

Neutralising

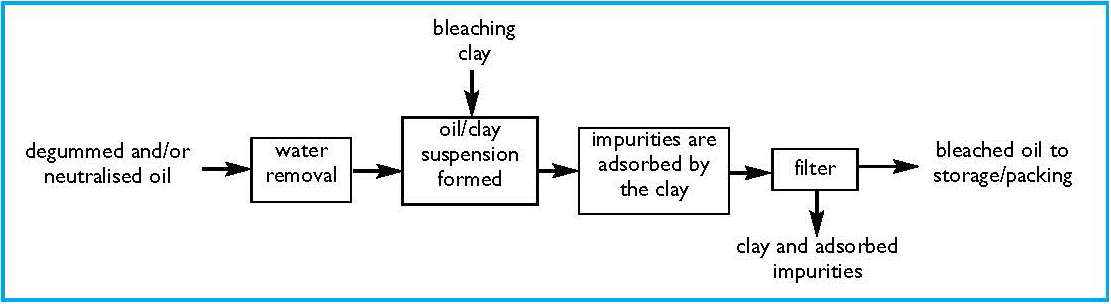

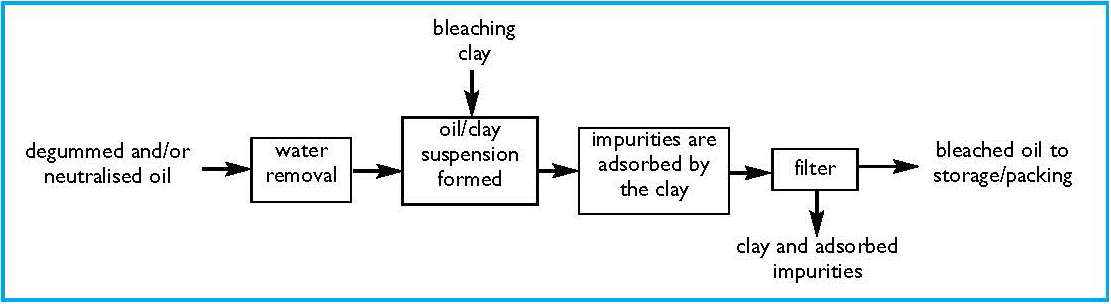

Bleaching

The wide range of oils processed by these methods leads to considerable variations in process requirements:

- Oils which tend to emulsify may be held in a vessel after mixing with the reagent to allow the emulsion to break before passing to the separator.

- In the degumming process the typical acid addition is 0.1 - 1%. Phosphoric acid is most commonly used, although citric acid is suitable for some oils.

- Process temperature is typically in the range of 50-70°C (120 - 160°F).

- Neutralisation process temperature may be higher, up to 95°C (200°F)

- The strength of the sodium hydroxide solution varies according to the acid content and oil type.

- During bleaching, a filter aid such as diatomaceous earth may be added to prevent the finer clay particles from blinding the filter medium

The Problem

Edible oil refining is normally a high volume, continuous operation. The reagent additions are traditionally carried out using low shear static mixers or inline agitators, which can lead to several potential problems:

- The acid and sodium hydroxide solutions make up only a small fraction of the total product, and must be reduced to the smallest possible droplet size to ensure intimate contact with the oil. Low shear devices with a relatively short dwell time cannot easily achieve this.

- With the clay addition, conventional agitation cannot rapidly produce an agglomeratefree, homogeneous suspension.

- Poor dispersion of reagents reduces process efficiency, leading to increased chemical consumption and waste.

The Solution

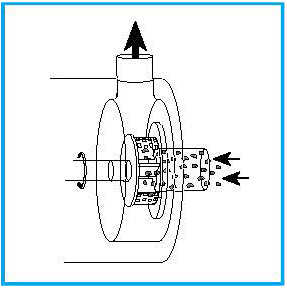

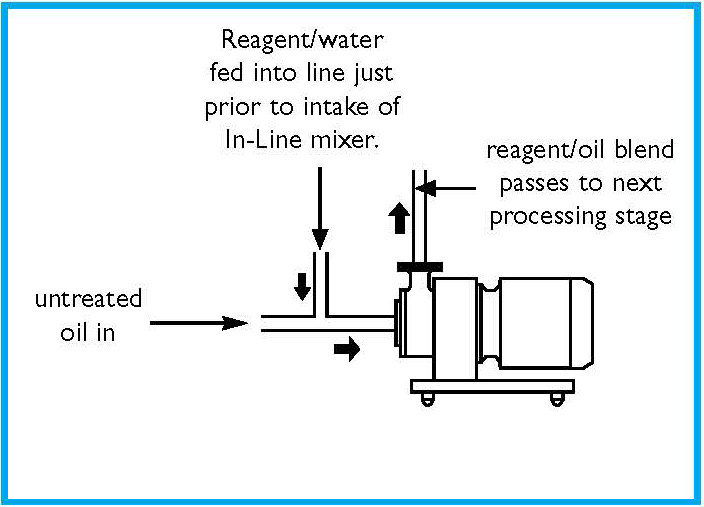

A Silverson High Shear Mixer can be used for the acid, sodium hydroxide, and clay additions. Easily fitted in place of the static mixer or inline agitator, the Silverson mixer can produce a fine dispersion of reagents in a single pass.This is achieved as follows:

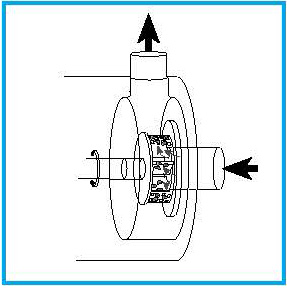

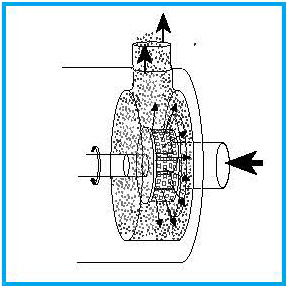

The reagent is introduced to the oil just prior to the intake of the Silverson mixer. The ingredients are drawn into the rotor/stator workhead and vigorously mixed

Centrifugal force drives the materials to the periphery of the workhead where they are reduced to a fine droplet/ particle size in the gap between the rotor blades and the inner wall of the stator.

Further reduction in particle size follows as the mixture is forced out through the stator, increasing the surface area of reagent exposed to the oil.This accelerates the reaction, and maximises the yield.

The Advantages

- Improved dispersion of reagents into the oil maximises the surface area exposed to the oil, accelerating the reaction

- Reduced chemical consumption and less environmental impact

- Rapid processing times

- Easily interchangeable workheads and screens allow the Silverson mixer to be adapted to optimise performance for processing a range of oils

Silverson offers a range of machines suitable for the acid and sodium hydroxide additions, and the Silverson Flashblend for the clay dispersion:

High Shear In-Line Mixers

- Aeration free

- Easily retro-fitted to existing plant

- Ideal for continuous processes

- Ultra Hygienic models available

- Multistage units available offering a greater degree of shear, resulting in finer particle size and faster processing times.

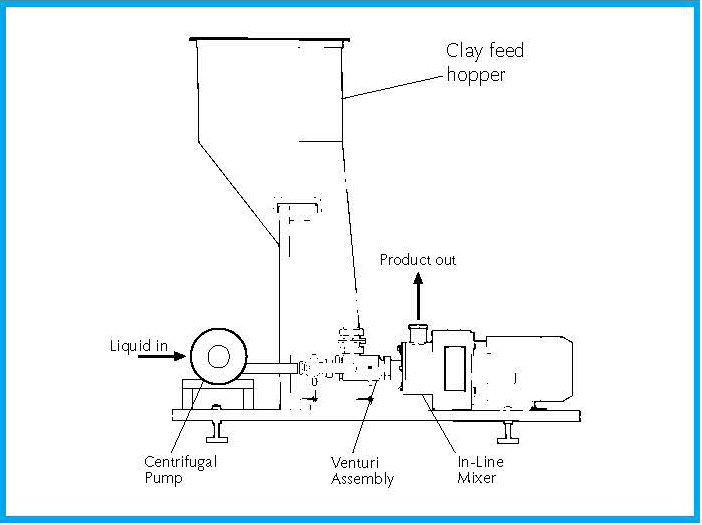

Silverson Flashblend

- Designed for high speed dispersion of powders into liquids

- Minimised cleaning requirements

- Minimum operator input required

- Easily automated