P Pharma Creams & Ointments

Production of Pharmaceutical Creams & Ointments

Pharmaceutical preparations for treatment of conditions such as rashes, skin irritation, stings, fungal infections etc. are normally supplied in the form of a cream or ointment as this provides an effective means of delivering the active ingredient directly to the required area. Products can be either a water in oil (w/o) or oil in water (o/w) emulsion, consisting of waxes, emollients and lubricants dispersed in an oil phase, and a water phase containing emulsifying, stabilising and thickening agents, preservatives and in some cases, colourant. Active ingredients are dispersed in either phase or added when the emulsion has been formed and allowed to cool.

The Process

Ingredients, formulation and product viscosity differ widely, however, a typical manufacturing process breaks down into four individual operations:

- Preparation of the oil phase. Flake/powder ingredients, sometimes dry blended in advance, are dispersed into mineral oil or silicone oil. Heating may be required to melt some ingredients.

- Hydration of aqueous phase ingredients. Emulsifiers, thickeners and stabilisers are dispersed into water in a separate vessel. Heating may be required to accelerate hydration.

- Forming the Emulsion. The two phases are blended under vigorous agitation to form the emulsion.

- Dispersion of the Active Ingredient. The active ingredient often makes up only a small proportion of the formulation; this must be efficiently dispersed to maximise yield and product effectiveness.

The Problem

Using conventional agitators a number of problems can be encountered:

- When added to water, thickening, stabilising and emulsifying ingredients can form agglomerates which agitators cannot break down.

- Similarly oil phase ingredients can form lumps which require shear to disperse.

- Ingredients must be fully hydrated to obtain the required viscosity and develop yield.

- Partially hydrated materials can build up on the vessel wall, in-tank baffles and parts of the agitator.

- Agitators cannot sufficiently reduce droplet size to form a stable emulsion.

- Active ingredients can be temperature sensitive. Cooling of the product before adding the active ingredient further increases processing time.

- Poor dispersion of the active impairs product effectiveness.

- Long mixing times and additional equipment may be required to obtain a homogeneous and stable finished product.

The Solution

A Silverson mixer can rapidly disperse solids into liquids, hydrate thickening and stabilising agents, break down agglomerates, and finely reduce particle and globule size to form stable emulsions and suspensions. Mixing times are dramatically reduced, while product uniformity and consistency are greatly improved. This is achieved as follows:

Stage 1

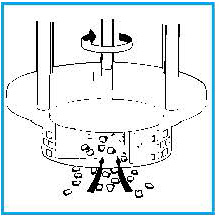

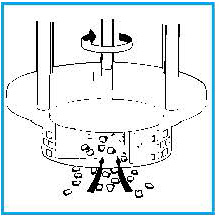

The high speed rotation of the rotor within the workhead creates a powerful suction which draws liquid and solid ingredients upwards from the base of the vessel into the workhead.

Stage 2

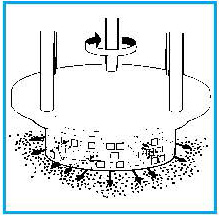

Centrifugal force drives the materials to the periphery of the workhead where agglomerates are broken down in the precision machined gap between the tips of the rotor blades and inner wall of the stator. The product is then forced out through the stator and circulated into the body of the mix. At the same time fresh material is drawn into the workhead.

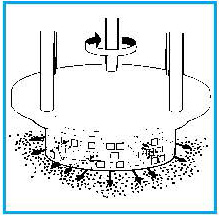

Stage 3

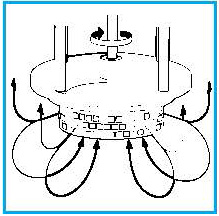

The intake and expulsion of ingredients through the workhead sets up a circulatory pattern of mixing in the vessel. All the ingredients pass through the workhead many times in a short mixing cycle, which progressively reduces particle size, and ensures that an agglomerate-free, stable and homogeneous end product is obtained.

The Advantages

- Stable emulsion

- Agglomerate-free mix

- Dramatically reduced mixing time

- Maximised yield of raw materials as thickening agents are fully hydrated and other ingredients fully dispersed

- In-tank baffles are not required, improving vessel hygiene

- Pre-mixing of powdered ingredients can be eliminated

- The aqueous phase can be produced at ambient temperatures, reducing heating costs. This also accelerates cooling of the mixture, further reducing process time and costs

- Consistent product quality and repeatability

The batch size, formulation, type of ingredients and the viscosity of the end product dictate which machine from the Silverson product range is best suited to individual processing requirements:

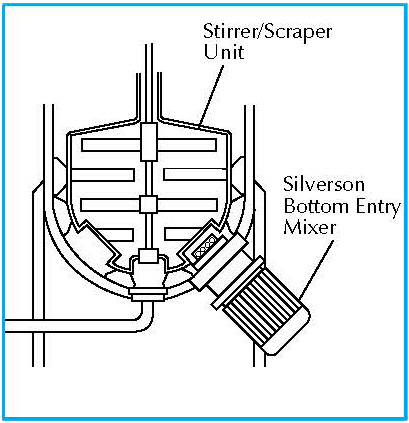

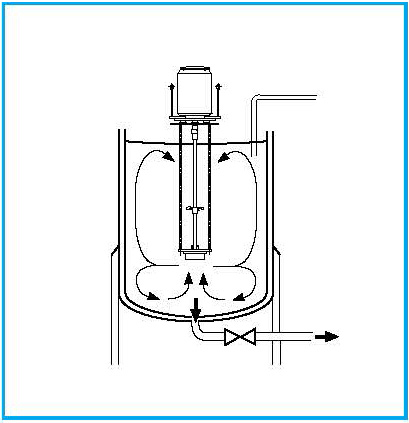

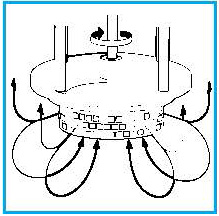

High Shear Bottom Entry mixers.

- The viscosity of some creams is such that they cannot be manufactured by a rotor/stator mixer alone. These can be processed with a Silverson Bottom Entry Mixer in conjunction with a stirrer/scraper unit as illustrated.

- Also suitable for products that increase in viscosity or solidify on cooling.

- The stirrer/scraper unit ensures that the output of the Silverson mixer is uniformly distributed throughout the vessel and prevents a localised heat build up on the walls of the jacketed vessel.

- Two-speed units available. Variable speed can be obtained with an inverter.

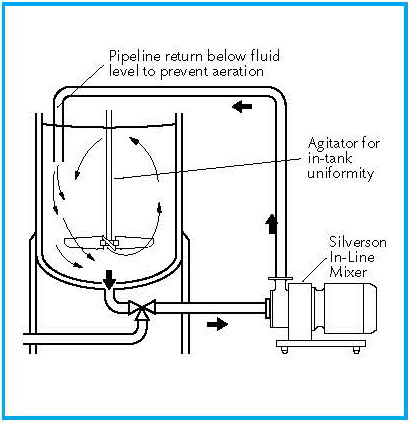

High Shear In-Line mixers.

- Ideal for larger batches.

- Aeration-free.

- Easily retro-fitted to existing process.

- Self pumping.

- Can be used to discharge vessel.

- FDA Approved, sanitary, CIP and SIP capable.

- Multistage units available

- Ultra Hygienic models available

- High viscosity products can be handled in combination with a positive displacement pump.

High Shear Batch mixers.

- Suitable for lower viscosity products.

- Batch sizes in the range of 200-500 litres

- Can be used on mobile floor stands

- Sealed units available for pressure/vacuum operation

- Small units available for R&D and pilot production.